Several years ago I began a search for detailed drawings and building plans for a Passive Solar Greenhouse. A Passive Solar Greenhouse is one that does not use costly, artificial heat sources such as electricity or propane to heat the greenhouse when it is cold, but instead utilizes the sun as a source of heat to heat water, masonry, stone or other heat holding material.

The main objective with passive solar greenhouses is to grow plants for extended periods, past their usual growing season, and year round preferably. An aquaponics system may be included in the project.

My search for a contractor that would construct a building on site to my design without architectural drawings or materials list came up empty. I decided to take my design to a builder of out buildings and sheds with the idea of building a shippable Passive Solar Greenhouse that could fill the void for those seeking the same thing I was: Year round (including in the dead of winter) fresh salads and veggies from a source I trusted, without high cost of winter greenhouse heating.

After some back and forth with the manufacturer regarding my design, we were able to produce a finished product. The PS greenhouse is 12′ x 20′ and designed with an open bottom, as in floor-less, to take advantage of ambient temperature of the earth. If you have been in a cavern you know what this means. For example, the temperature inside Luray caverns near my home is a constant 54F degrees year round.

Passive Solar Greenhouses differ from traditional greenhouses in that only the South facing side has glazing that allows sunshine in, the remaining sides being insulated. In addition, in my design, the North facing wall is covered with black plastic barrels (50 and 58 gallons each) that act as heat batteries.

The North facing wall is also insulated with R13 insulation and further insulated by the use of Reflectix reflective insulation. The Reflectix product not only adds to the insulation value, but bounces the sunlight around inside the Greenhouse to better benefit the plants.

Physics lesson: A drop of one degree per pound of water releases 1 BTU (British Thermal Unit, the traditional measurement of heat). My barrels should represent at least 500 gallons of water. This is a weight of about 4150 pounds (water is 8.3 pounds per gallon) If the water temperature drops 10 degrees then the barrels will release 41500BTU’s of heat. A 20 degree drop would mean 83000BTU’s of heat. For perspective, typical home furnace ratings start at 80000 BTU’s.

The addition of an insulating curtain to cover the glazing and retain heat in winter (as well as shade from heat in summer) is an option in this design. There are ventilation fans to cool things off when the heat gets too high, year round.

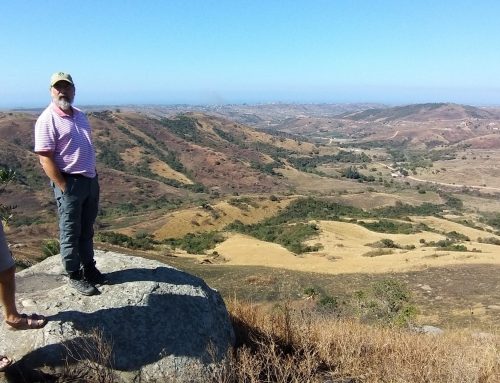

Included here are some early photos of the project. I will have additional updates from the project along the way. If you are interested in more information on obtaining one of our shippable Passive Solar Greenhouses let me know!

Mike, did you consider excavating below the frost line for a little more geothermal stability, or was it too cost prohibitive?

We did indeed. The original plans were for it to be 4 feet in the ground. Costs and difficulties with excavation made the build more conventional UNfortunately

Hi there, Michael, Are you still selling the Passive Solar Greenhouse Kits?

I’m in North Carolina. Interested in kits or blueprints/design to build one for are farm.

Rufus